Shell Joins Undertaking that Guarantees to Change Subsea Restore Recreation Utilizing 3D Printing Tech

Oil main Shell has partnered with Kongsberg Ferrotech in a venture that’s creating instruments to restore subsea property utilizing 3D printing know-how.

“Since 2021, Kongsberg Ferrotech has labored in a joint trade venture with the companions Equinor, Gassco and SINTEF to develop and check superior 3D printing applied sciences for in situ, steel to steel, repairs of underwater property. The venture achievements have been acknowledged available in the market and Shell is now becoming a member of the workforce,” Kongsberg Ferrotech mentioned.

The companions of the joint trade venture are of the opinion that the brand new strategies, in growth, characterize a game-changing manner of conducting subsea repairs.

“Additive manufacturing for lifetime extension of subsea property, is predicted to have nice monetary and environmental advantages for put in in addition to future subsea property. 3D printing meets the primary standards for sustainability – scale back, reuse, and recycle. The venture has recognized a number of functions comparable to restore of cracks, dents, and substitute of misplaced supplies, the place the know-how can be very helpful in comparison with conventional strategies,” Kongsberg Ferrotech mentioned.

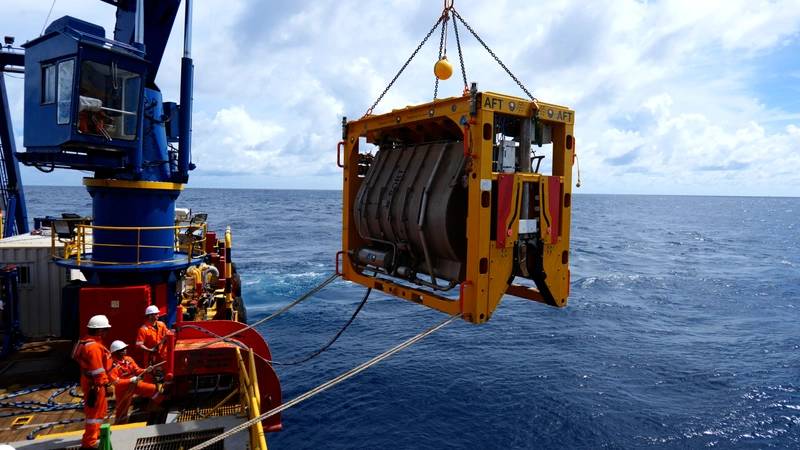

3D Printing & Subsea Robots Kongsberg Ferrotech’s Nautilus subsea pipeline restore instrument was lately deployed in Thailand for PTTEP. Picture from Kongsberg Ferrotec

Kongsberg Ferrotech’s Nautilus subsea pipeline restore instrument was lately deployed in Thailand for PTTEP. Picture from Kongsberg Ferrotec

In keeping with the corporate, the venture has reached essential milestones on the way in which and is at present within the technique of qualifying the 3D printing know-how for cracks and dents.

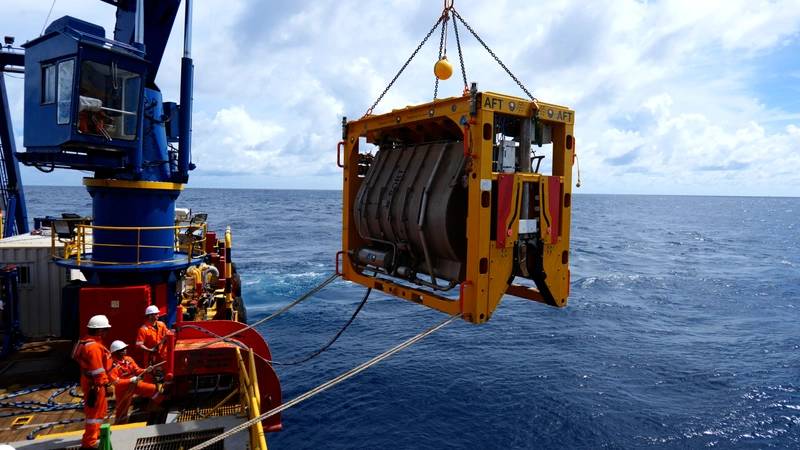

3D printing know-how can be built-in into Kongsberg Ferrotech’s Inspection, Restore and Upkeep (IMR) robots.

Within the restore course of, a dry setting is created to supply documented, high-quality repairs with out disrupting ongoing operations.

“We’re completely happy to be a part of an thrilling growth. After we found this joint trade venture, we realized that the restore strategies have many functions inside Shell’s international operations. The know-how is of nice curiosity to Shell and matches properly into our portfolio of superior know-how for subsea robotics and 3D printing. We’re trying ahead to a detailed collaboration with our trade companions, says Angeline Goh, 3D Printing Know-how Supervisor at Shell.

Contained in the underwater habitat. On this robotic, 3D printing know-how can be built-in. From left: Torger Tokvam (design engineer Kongsberg Ferrotech) and Steven McAlpine (Undertaking Execution Kongsberg Ferrotech).

“We’re excited to welcome Shell to the workforce and contemplate their resolution as an essential recognition of the potential represented by our know-how. With one other international associate onboard, we’re capable of adapt our know-how in direction of a big international market. Along with our companions we’re now getting ready for the world’s first check of 3D printing repairs in demanding ocean areas, says Torgeir Bræin, CTO at Kongsberg Ferrotech.

“The unique companions are happy to see that this modern initiative is being acknowledged within the international subsea market, confirmed by Shell becoming a member of the workforce. Shell’s participation will strengthen the workforce significantly with extra sources, experience, functions, and market.

“The robotized 3D printing venture contributes to the vitality transition by offering prolonged lifetime of present and future underwater property. The joint trade collaboration is supported by the Analysis Council of Norway.

In keeping with the venture companions, the know-how can be appropriate for subsea oil and gasoline, hydrogen transport grids, wind farms, transmission cables and so on.